Weaver Floor Jack Rebuild

These jack cylinder service kits are for minor cylinder repairs only if additional servicing is required have repairs performed by a qualified hydraulic jack repair center.

Weaver floor jack rebuild. Parts and repair kits for weaver automotive in ground and surface mounted lifts can be found at parts4lifts com. We also sell metric and standard seals. No opened kits or installed parts may be returned for credit and no returns will be accepted after 30 days from date of shipment. Speaking as a lifelong mechanic weaver products that i have used and owned are overbuilt and usually a joy to operate.

16 item wa 73 series all series floor jack 4 ton hydraulic repair seal kit. The design of this floor jack is elegant yet simple. It is easy to use and easy to repair if service is ever required. I am repairing a 3 ton floor jack but most ja.

They are professional quality and in recent years have begun to escalate in value. We carry the entire weaver jack parts line. Jack model numbers and repair kit numbers shown are for reference purposes. Add the climbing pin to the runner and then install the cross pins onto the climbing pins.

The weaver line of long frame hydraulic service jacks uses a time proven design that has been tested in use for over 80 years. Lazzar s hcrc is a leading supplier of repair parts and seal kits for floor jacks air hydraulic pumps hand pumps and rams. This video will show you the most common way to repair a floor jack that is leaking fluid and thus won t lift. Click here to view seal kits.

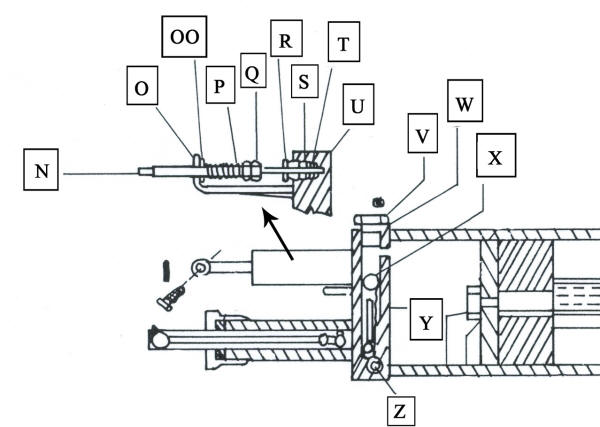

15 item wa 72 series all series floor jack 2 1 2 ton hydraulic repair seal kit kit 04450 oem kit 5 968. Installation instructions for weaver seal kits. Insert the reverse switch and the spring into the larger runner. Add lubrication grease to all running parts and then push the pitman pin into the handle.

See reviews photos directions phone numbers and more for weaver hydraulic jack repair locations in memphis tn. The first step to rebuilding your floor jack is to restore the running gear. Use safety solvent or mineral spirits to clean parts blow dry with compressed air.