Web Adhesive Lamination

Extrusion and adhesive lamination.

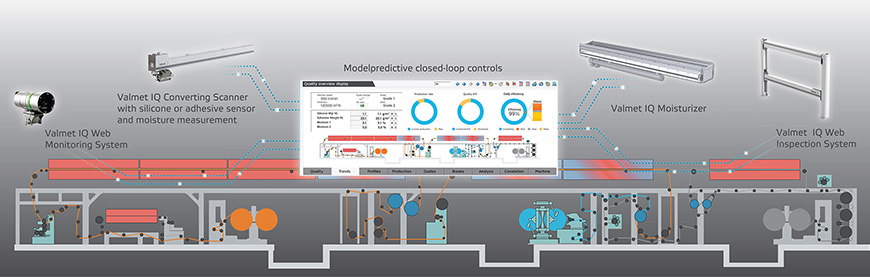

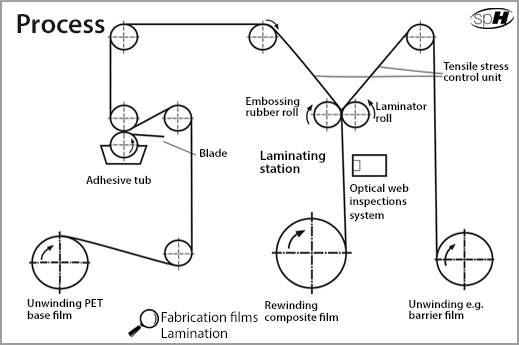

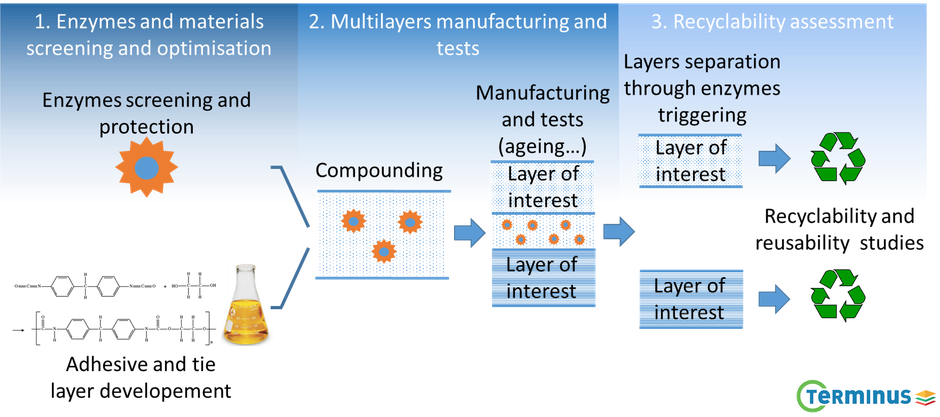

Web adhesive lamination. Lamination involves combining sheets of different materials into a single layer using a mixture of adhesives pressure and sometimes temperature to bond the materials together see also chapter 14. Incorporates auto web guidance and web auto tensioning using plc technology with all their web laminating systems. The lamination process is when a single web makes two or more independent webs. What is adhesive laminating.

Flatbed web adhesive lamination flatbed lamination is a new method of lamination for roll goods and sheets that utilizes dry thermally activated adhesive systems that do not require long drying curing tunnels to process. Line speeds of these complete systems are capable of 10 fpm 3m to 150 fpm 45m. Adhesive laminating is one of our more popular types of materials we produce. Aluminium foil is laminated on web fed rotary equipment which sometimes includes a coating unit to add further protection.

In regards to laminating specifically the term web means the path the material takes through a process of unwinding converting and rewinding. We complete this process using wax wax lamination melted plastic resin extrusion lamination or liquid adhesives adhesive lamination. 875 rpp web laminating system capable of laminating multiple webs of aluminum adhesive films and other various webs.

.jpg)