Weld Bend Test Standard

1 1 these test methods cover bend testing for ductility of materials.

Weld bend test standard. It is also mentioned in an article published in section 7 of issue 13 of practical welding letter for september 2004. Scope 1 1 this section covers the bend testing of fillet welds. A semi guided bend test in which the specimen is bent while in. Next the flat strap.

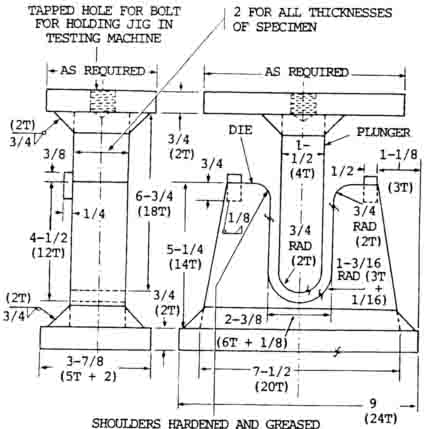

Department of education to develop a series of standards and a program for the recognition of welders based on welding performance testing and practical knowledge tests. 2 1 x 1. 8 beveled edges 4 test plates total 150 00 description. 1 1 this test method covers a guided bend test for the determination of soundness and ductility of welds in ferrous and nonferrous products.

1 thick set astm a36 qty. Weldbend is proud to be america s choice for domestically manufactured carbon steel butt weld fittings flanges 60 news. The standard gives the requirements for guided bend test specimen preparation test parameters and testing proce dures but does not specify the requirements or accep tance criteria. 131 135 138 or 311 two bend test samples must be removed.

4 plates for 3g 4g backing material weld tabs 3 w x 5 l x 1 thick astm a36 hot rolled plate each plate beveled at 22 5º beveled along both edges of the length backing material 1 x 1 4 flat bar x 7 long qty. Search view print download all in one place. In cases where bend testing is used to supplement radiography when evaluating welding samples carried out using processes. The industry leader in carbon steel weld fittings and weld flange products from 1 2 thru 60 english inches version interact live with weldbend s product catalog.

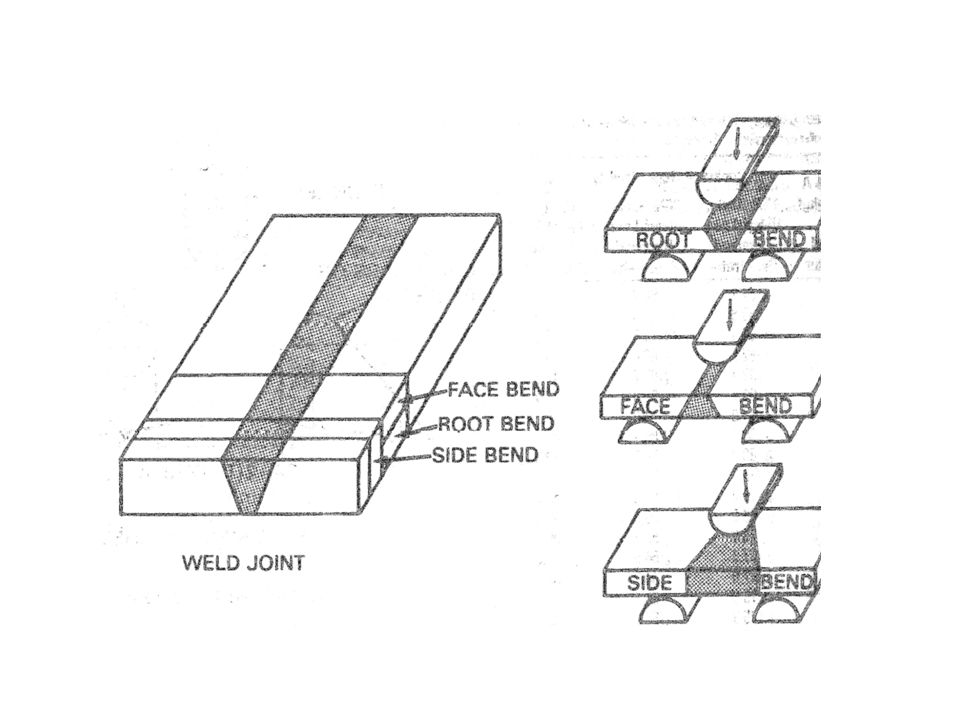

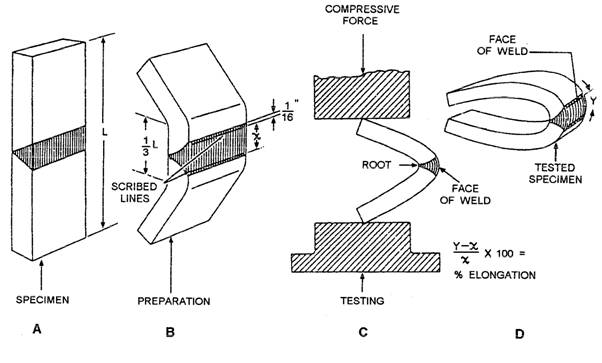

Included in the procedures are four conditions of constraint on the bent portion of the specimen. Two plates are welded together and a flat strap of metal is cut from the welded plates. A guided bend test using a mandrel or plunger of defined dimensions to force the mid length of the specimen between two supports separated by a defined space. Visit the news page for up to date information about weldbend carbon steel weld fittings and flange products and industry news.

The concept of a bend test for welds is simple. Flaws not shown by x rays may appear in the surface of a specimen when it is subjected to progressive localized overstressing. This procedure was briefly addressed in our page on welding testing. Aws d1 1 structural welder performance qualification test coupons.

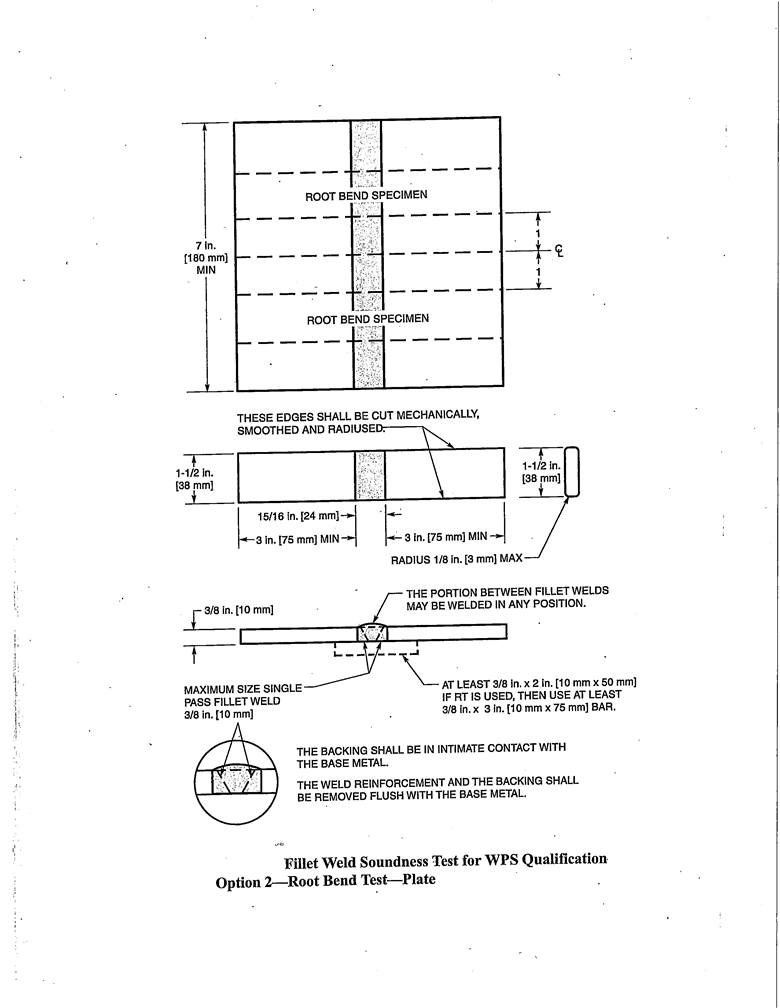

Understanding bend tests many welding codes require bend tests as part of the testing required to qualify welders and welding procedures specifications wpss. The aws schools excelling through national skill standards education sense program began in 1993 with the award of a grant by the u s. Explore all products and technical data. When applied to welded specimens it evaluates both the ductility and soundness of welds without instrumented equipment.

One sample should be bent with the face outward face bend test and the second bent with the root side of the weld outward root bend test.

.jpg)