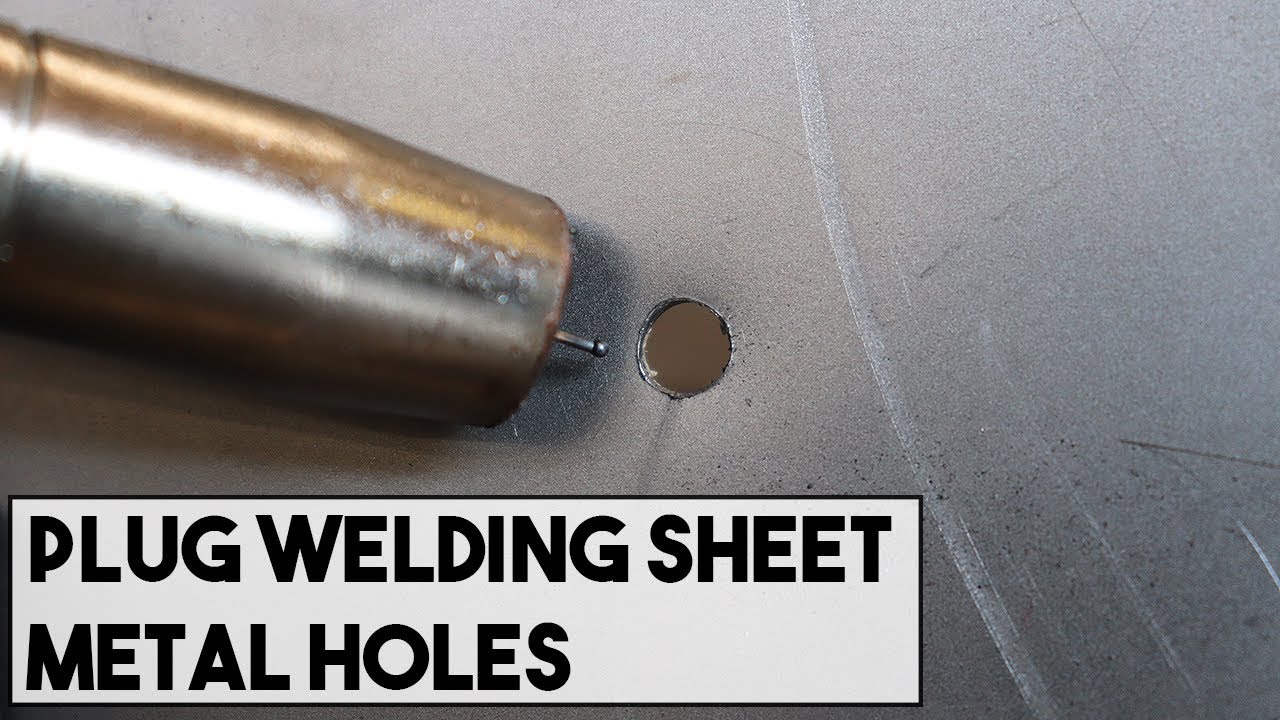

Welded Sheet Metal Pin Hole Filler

Techniques for welding sheet metal.

Welded sheet metal pin hole filler. Best deal on goodyear air hose check this out https amzn to 3b5cjvy how to fix a hole without welding no warping. Holes larger than 1 4 need to be filled with metal. By filling in holes you stop rust in its tracks and ensure the metal lasts longer. Get a tig 200.

Body filler is a simple way to repair freshly cleaned holes. A 5356 filler metal also works for 5052 materials specifically. Perhaps a simple rivet or sheet metal screw can be secured in the hole. If the hole needs to contain a liquid a rubber washer can go on the sheet metal screw to render it water tight.

To prevent burn through and warping don t whip or weave the torch. Holes in thin metal can be filled with plugs. In this video matt goes over how to fill holes in a fender using a mig welder and a tig welder. I then used the templates to trace out the patch panels on some sheet metal.

Mattm rust pin holes can happen on vehicles as new as a few years old in some cases. A small magnet will help keep the filler metal in place while you weld. The kind of plug to use depends on how the thin metal is being used. Easy to do and really strong.

How to repair rust pin holes without welding posted. If you know how to weld take advantage of your tools for a longer lasting repair. The more time the arc is in an area the hotter it. Or less holes in steel aluminum fiberglass and plastic body panels while minimizing sanding damage and the amount of required surface preparation.

October 8 2018 by. Then the hole was welded using the stitch method. After slicing the patches out with a cutoff wheel next came the bending hammer and dolly session until the patches matched the holes and fit snug and flush into the flanged seat. You might not have the money to pay an auto body shop to perform the repair or the tools to cut and weld a new patch panel in.

I used a piece of pvc pipe a vice mount miniature metal break and body hammer kit. Typical aluminum alloys for sheet fabrication are 3003 and 5052. You need to give a little extra time for the weld to cool before moving on to the next one as the weld area is so small.