Welding Overlap Seam Auto Sheet Metal

Don t attempt to weld thin materials like sheet metal with flux cored wires which put more heat into the base metal.

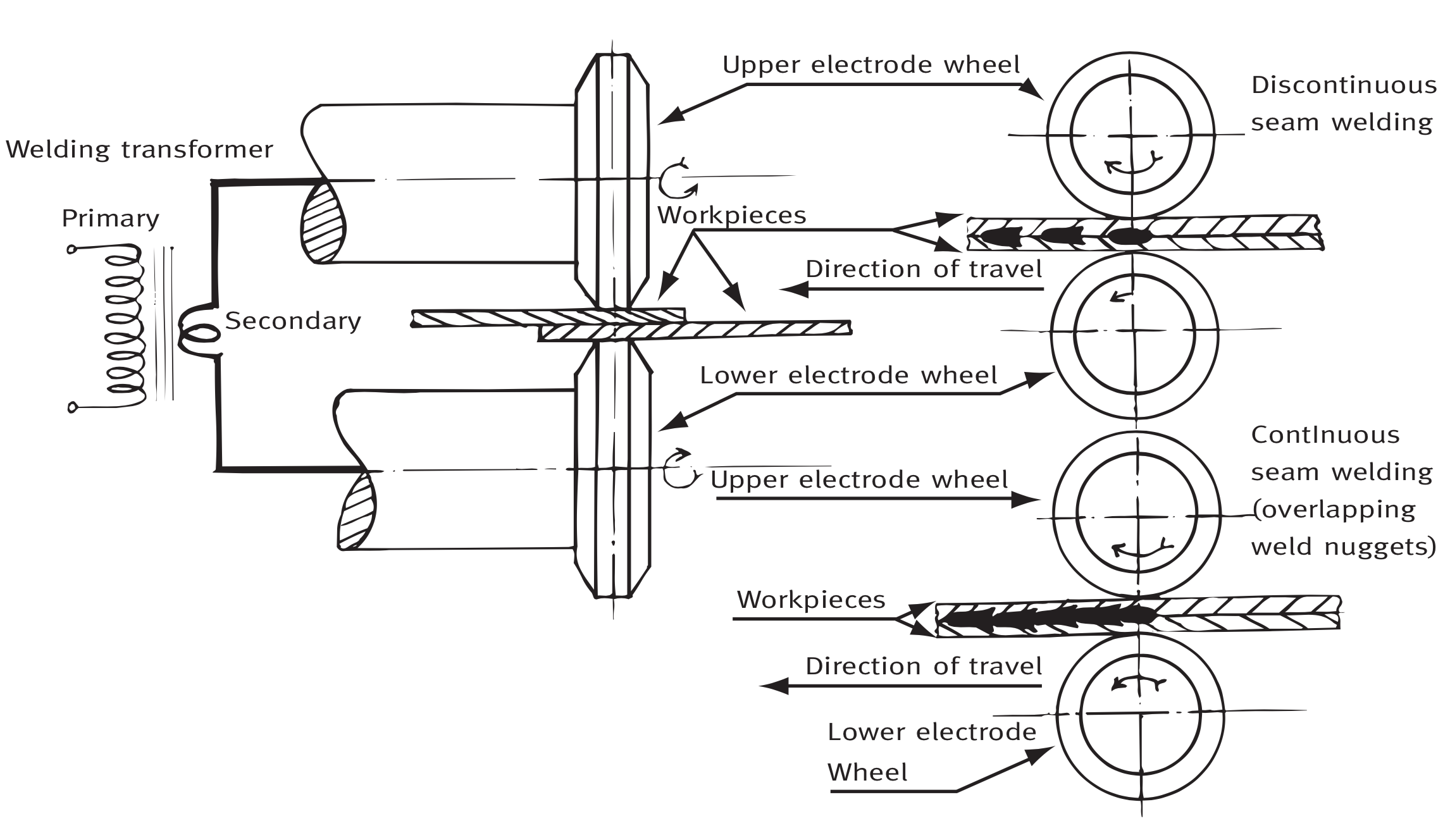

Welding overlap seam auto sheet metal. To be specific if i have two sections of say 1 8 x6 x6 steel plate that overlap each other by 3 and say i want to weld the two parallel pieces together. Spot welding is usually used to join a panel of overlapping sheet metal parts that are usually 3mm thick. The majority of the sheet metal welding i ve done was with a 90 amp 110 volt welder. Its primary usage is in welding auto body and sheet metal.

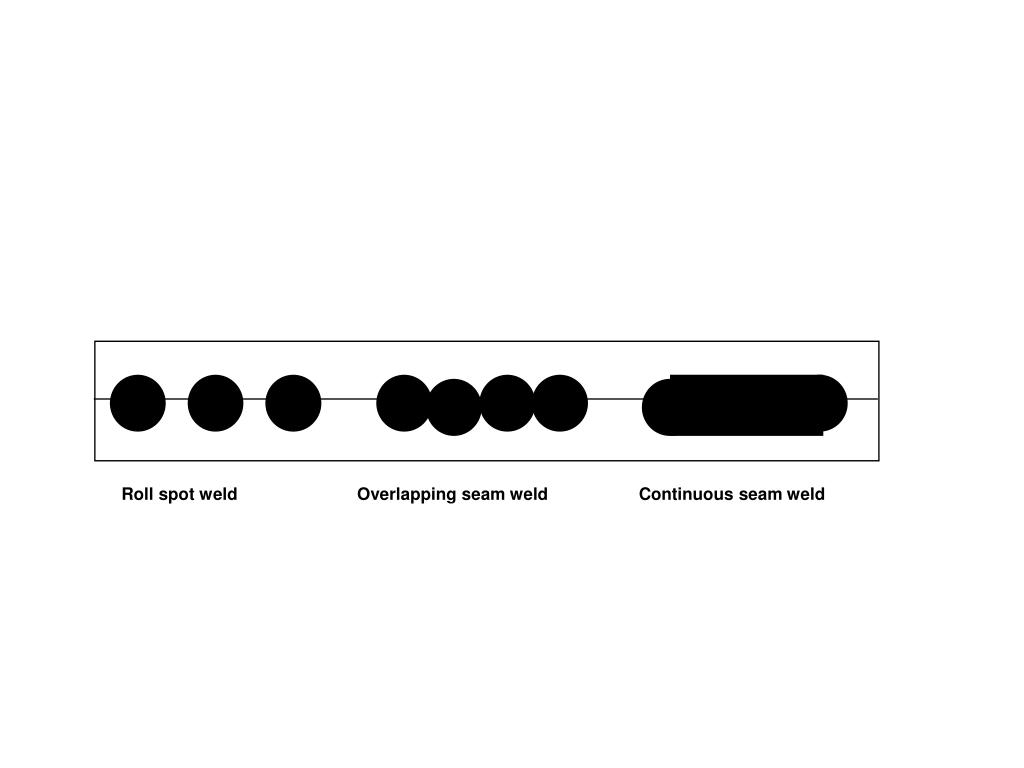

Lakeside autobody 44 996 views. And let s say i want to stitch weld the seams that is not a continuous weld for the full length of the overlap. Thus spot welding diameters go from 3mm to. The best two electrodes for welding auto body sheet metal is either ceriated tungsten or thoriated tungsten.

You can now place a tack weld between the clecos but be very careful to make sure the panels are perfectly even. My question is when i weld in the new sheet metal should i overlap the existing metal or cut a perfect patch and seam weld the metal. To weld sheet metal with solid wires use electrode positive ep or reverse polarity. The ration of thickness should not exceed 3 1mm.

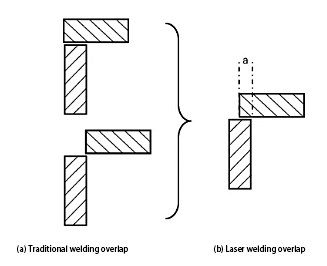

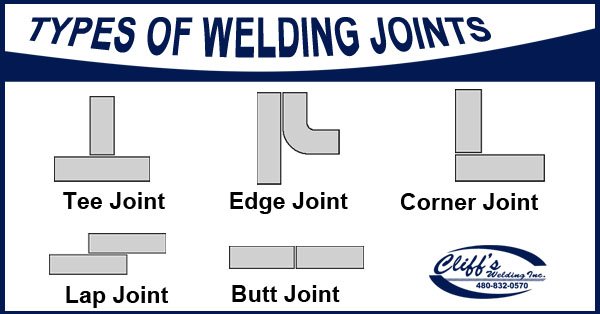

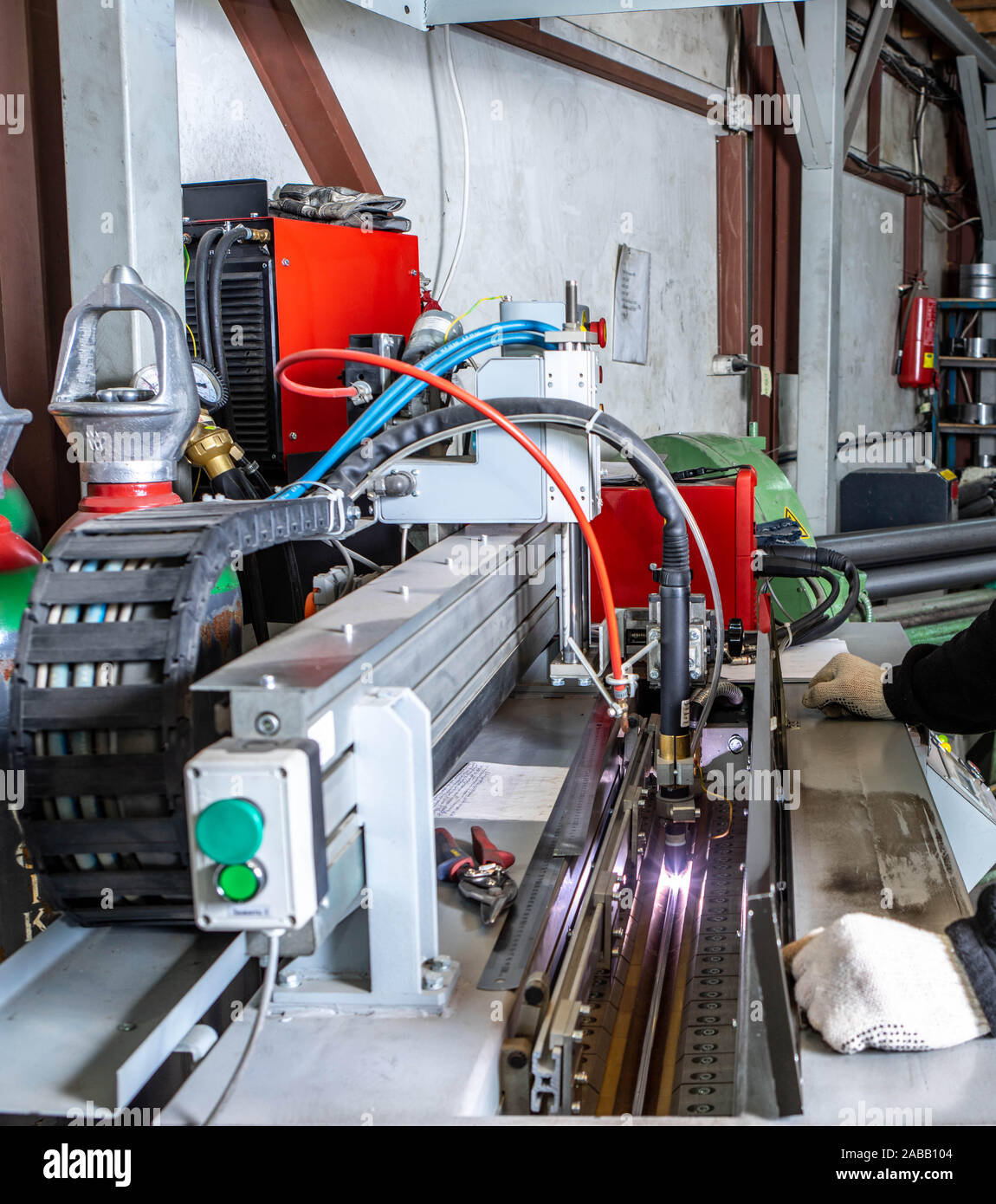

Lap joints are made by overlap ping small amounts of metal and welding the exposed edges of each section to the other on one or on both sides. How to plug weld auto body sheet metal prevent. This video shows how to mig weld long seams in auto body repair. The holes are in the floor and not the outside body.

Tig welding sheet metal. A seam is then made by cutting down the middle of the overlap with a west cut 4 inch cutoff wheel and peeling back the remaining strip of metal. Because it will have you a lot more control over the whole process and it is more forgiving in case you do anything wrong. Mig welding is the preferred method for most automotive bodywork and since sheet metal is the thinnest of metals a large expensive mig unit is usually not required.

Ditch a 1 8 inch tungsten electrode for something much smaller like 1 16 inch tungsten. This of course creates a double thickness of metal at the joint overlap something that can be difficult to hide without using excessive amounts of filler. I will be welding soon on a couple small spots on my 69 camaro.