Welding Sheet Metal Blowing Holes

To weld sheet metal with solid wires use electrode positive ep or reverse polarity.

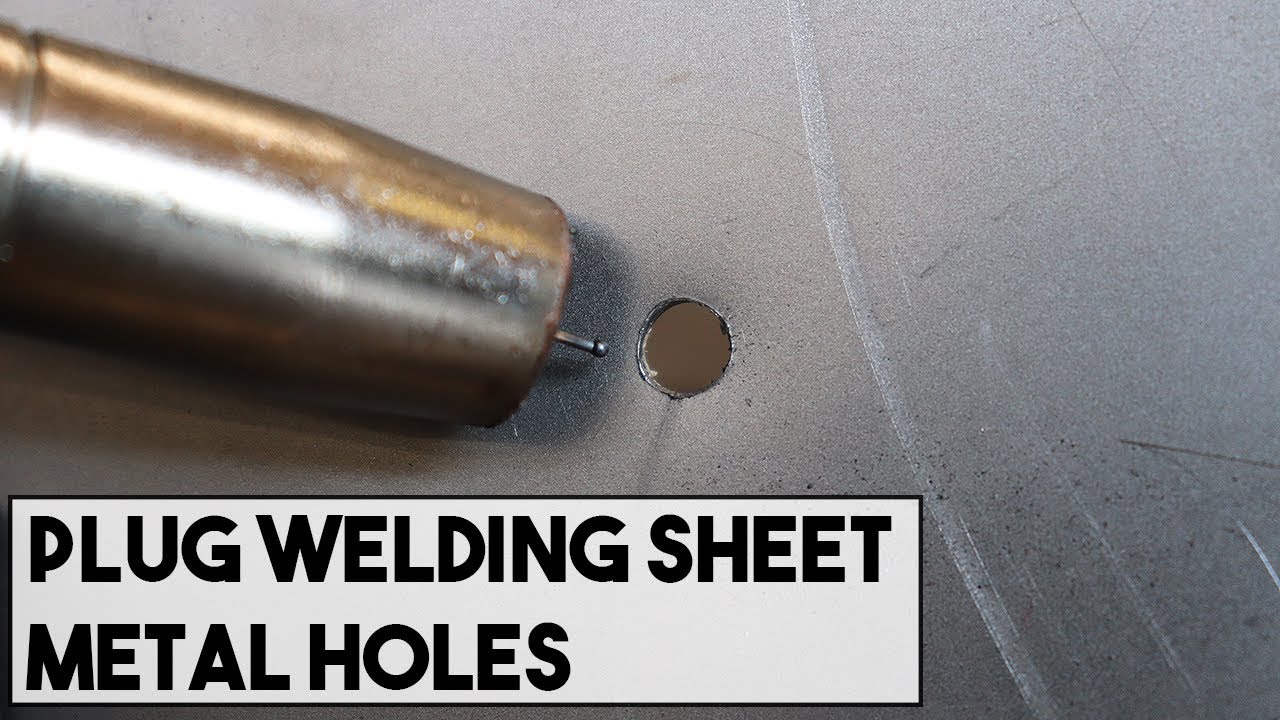

Welding sheet metal blowing holes. Andy gives helpful insights and tips to mig weld thin sheet metal. Welding wire is too thick it will take more heat to melt the wire than the substrate and can make it even more prone to blowing holes in the panel. How to mig weld sheet metal posted. Stick welding sheet metal with 6013 rods.

Here s a few tips on repairing rust holes in car body panels. The aim with this technique is to melt a bit of metal and then let it cool slightly before melting the next and it s a handy way to avoid blowing holes. Forget the larger 1 8 inch tungsten electrode and use a smaller one. Tig welding sheet metal.

Don t attempt to weld thin materials like sheet metal with flux cored wires which put more heat into the base metal. For thinner gauge sheet metal like 18 or 20 gauge we suggest 023 6mm wire in your mig welder. The thin metal technique is a non continuous process that is used for thin metal such as car body panels. In this video im showing you the process i use to do small rust repairs where a complete panel.

I m welding very t. June 9 2017 by. This is the thinnest sheet metal i have ever welded using this process. In this article we are taking a look at how people should go about welding sheet meta l what kind of wire and shielding gas need to be used.