Welding Thin Copper Sheet

Sheet metal welding tips.

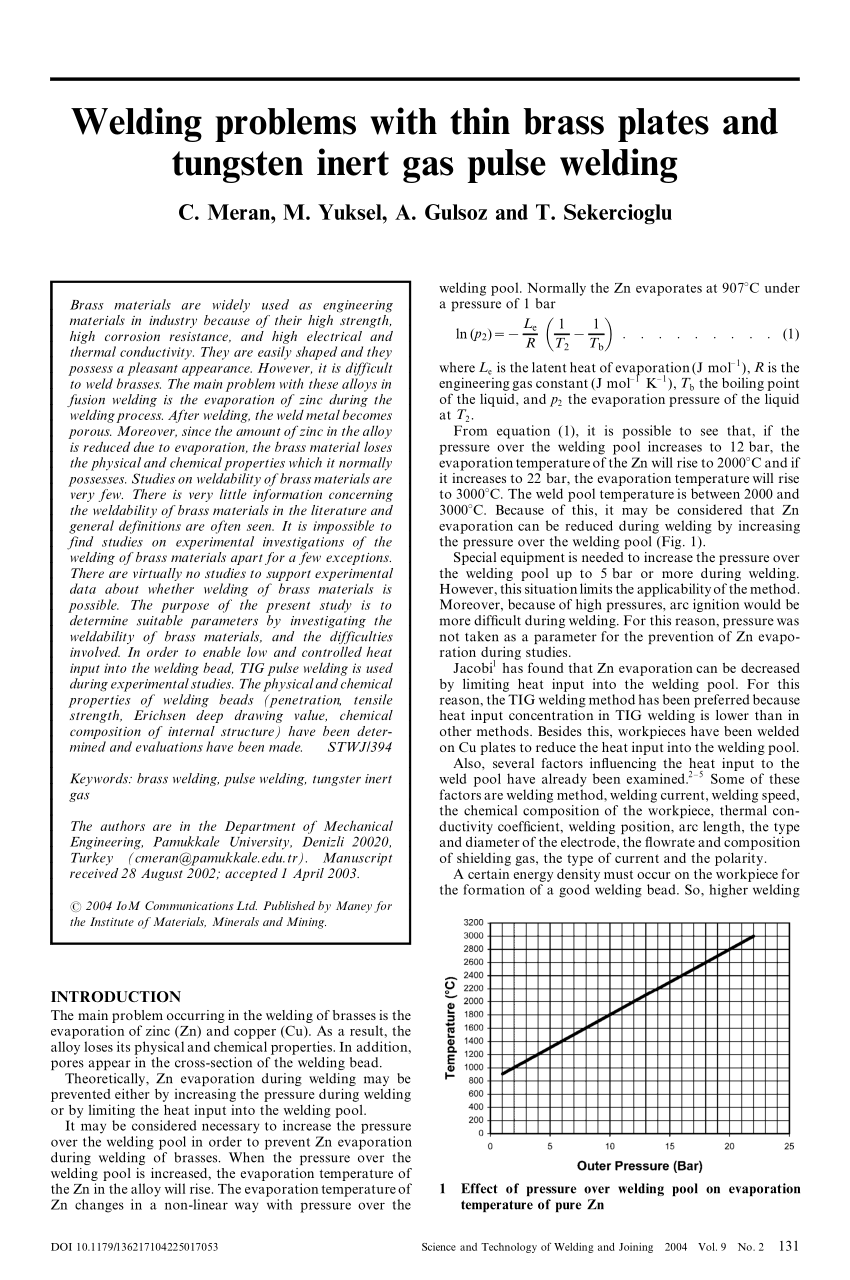

Welding thin copper sheet. The total energy consumption required for welding copper has been mathematically reduced by 84 percent compared to infrared lasers and by as much. How to weld sheet metal welding thin metal with tig and mig processes. Fit up and joint design. 6 4 mm or more.

P deoxidized copper contains low amounts of oxygen but tends to have up to 0 05 phosphorus and 0 05 arsenic which can release fumes. In the past we have. Copper or aluminum bars are preferably used as they have the ability to dissipate heat faster. Oxygen free copper will allow copper to retain the original bronze color after welding by preventing oxidation.

Don t attempt to weld thin materials like sheet metal with flux cored wires which put more heat into the base metal. Https goo gl frdnss in this episode of tig time wyatt shows you how to weld copper. The final weld will be the same color as the base material. Laser welding copper to aluminum or steel can even be achieved with copper powder and thin copper foils.

With a little grinding the finished piece will look as though it wasn t welded at all. Trim thin strips of waste material from the projecting copper and use them as welding rods. To weld sheet metal with solid wires use electrode positive ep or reverse polarity. The backhand method is preferred for thicknesses of 1 4 in.

When welding thin sheets the forehand welding method is preferred. Forget the larger 1 8 inch tungsten electrode and use a smaller one. The thinner sheets 02mm and 03mm are too thin in comparison to the diameter of the wire and holes are created in the sheet when welds are attempted. 3 2 mm thick a plain butt joint with squared edges is preferred.

Welding 101 by adam mason. Sheet metal welding demands really tight fit ups. For sheets up to 1 8 in. Tig welding sheet metal.

In a situation when a. The weld should be started again and continued until the seam weld is completed. Subscribe for new videos every monday and friday. Carbon steel and 18 ga.

Gas metal arc welding gmaw is an effective method for joining light gauge metals such as carbon steel and austenitic stainless steel.