Welding Up Small Holes In Sheet Metal

Imagine a butt weld on 20 to 24 gauge metal.

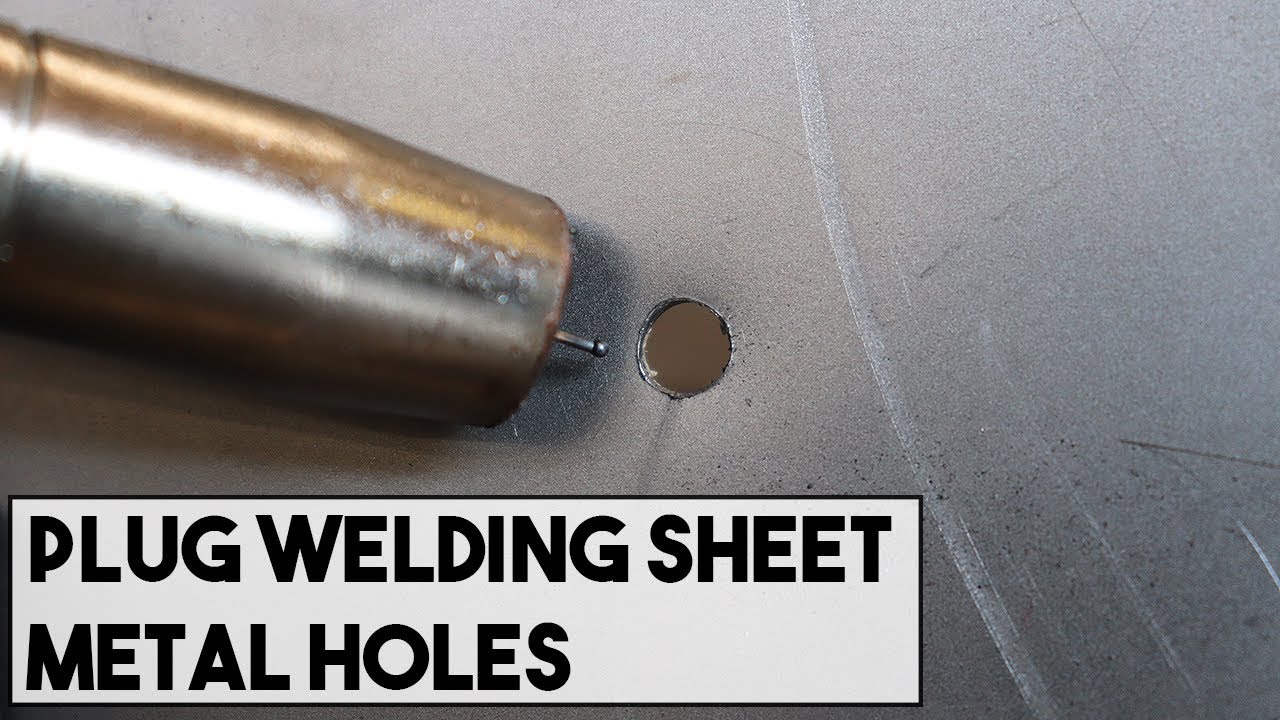

Welding up small holes in sheet metal. For these types of holes i start by cleaning the area around the hole with an angle grinder and flap disc. Make sure you always work with a small wire diameter to avoid making holes in your sheet metal. If the parts fail to touch each other for even 1 16 inch you have created a hole that invites burn through and a gap that can t absorb the heat. Make sure to use an electrode wire that is thinner as it uses lesser heat and prevents blowing holes on to the sheet metal.

Try going for a wire of 023 inches when welding sheet metal. Fit up and joint design. The easiest holes to fill are small holes about the diameter of a pen or smaller. If you are going to weld on thin sheet metal such as car body parts then you re going to have holes to weld from time to time.

In this video im showing you the process i use to do small rust repairs where a complete panel. Welding thin metal demands tight fit up. Small wire diameter will let you have flexibility if you mess up anything. Imagine a butt weld on 20 to 24 gauge metal.

Try welding with a scrap sheet metal piece and practice many times until you start working on more important projects. Never go for a thinner base metal for the auto body sheet welding to get the best result out of it. This may be due to burning through the thin sheet metal welding molding holes fabrication or other reasons needed. Here s a few tips on repairing rust holes in car body panels.